Hi All,

I'm new to this site. I'm hoping someone can help me. The car smokes terribly. White smoke with the smell of unburned diesel fuel. Car runs so-so. Mostly it's a smoke problem. I've checked the injectors - they work. Cleaned the throttle body. Used Diesel Purge type product. I tried adjusting the injection timing. Nothing makes a lsting difference (short term improvement but gets worse all the time).

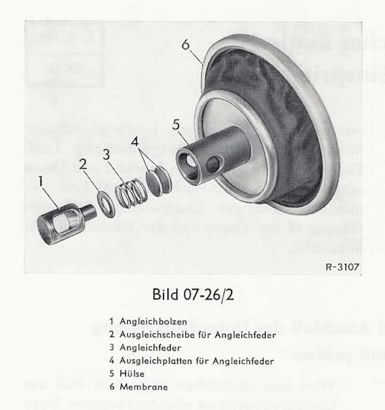

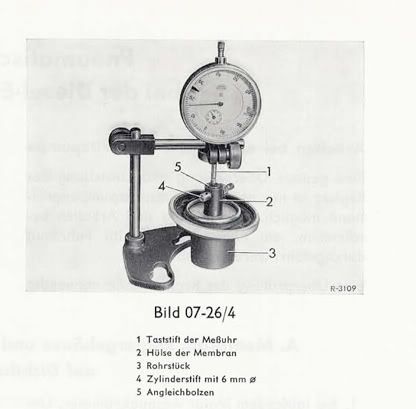

I'm wondering if the injection pump diaphram (governor) has a whole in it and I'm getting too much fuel for the amount of air the throttle body allows. If I suck on the tube it doesn't hold vacuum (engine off); shouldn't it? if I pinch the tube while the car is running the throttle goes up; however if I remove the tube the throttle goes way up as I assume it should.

Any thoguhts?

Thanks,

Greg

I'm new to this site. I'm hoping someone can help me. The car smokes terribly. White smoke with the smell of unburned diesel fuel. Car runs so-so. Mostly it's a smoke problem. I've checked the injectors - they work. Cleaned the throttle body. Used Diesel Purge type product. I tried adjusting the injection timing. Nothing makes a lsting difference (short term improvement but gets worse all the time).

I'm wondering if the injection pump diaphram (governor) has a whole in it and I'm getting too much fuel for the amount of air the throttle body allows. If I suck on the tube it doesn't hold vacuum (engine off); shouldn't it? if I pinch the tube while the car is running the throttle goes up; however if I remove the tube the throttle goes way up as I assume it should.

Any thoguhts?

Thanks,

Greg