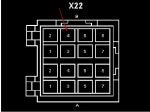

I have a problem with my 02 ML320 AC . It blows only ambient air. The Compressor (nor the aux cooling fans) are engaging when I turn on the AC. This problem was intermittant but now it does not work at all. When it was intermittant the AC would blow only warm air then other times when I would either turn it on and off a few times or restart the car it would work normally. By blowing warm air I mean the compressor (and fans) weren't engaging. I have refrigerant in the system about 100 psi (both sides) static and (when it was working) normal high and low side pressures. I have checked the fuse (44) for the fans (ok) replaced the fan relay (#26) and checked to see if I had power to the correct terminals to the fan relay. I do. The fans will come on if I remove the relay and jumper the correct terminals. I removed the plug off the low pressure switch to check for corrosion (none) . It seems as whatever is suppossed to tell the compressor ( and fans) to engage isn't doing so. I've read some of the forums here on the subject and tried to troubleshoot what I could as stated above but now I'm at a loss. Any Ideas? Ac control panel? I've read maybe the AAM (hopfully not!! Please Help . Thanks

Nick

Nick