Why warning? Because this is a case when 70 cents (no kidding) failing seal can cost hundreds if not thousands dollars damages.

Whoever has the car with 320cdi engine (I bet it might apply to other engines) better check it out before warranty expires. The small leak can go undetectable for thousands of miles till the damage extends to big proportion.

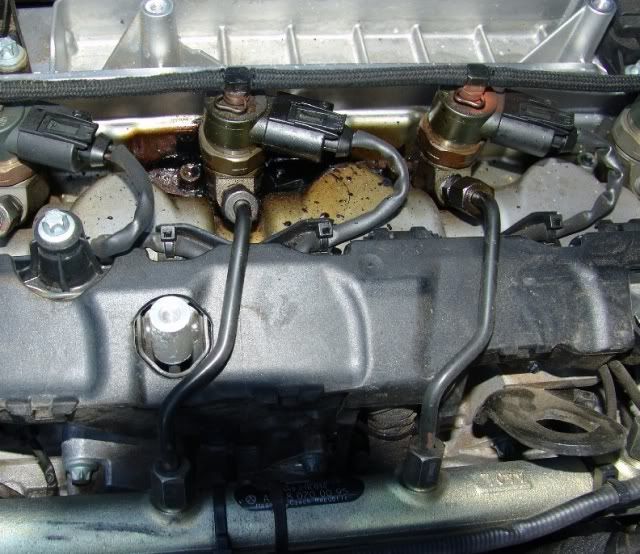

Coming to technical part. Being curios DIY I took the top engine cover and head foam insert off -to discover look like this

![Image]()

At the moment with engine running I heard some hissing coming from the injector in the center, but it was actually the one on right hand side that gave me big trouble. I did some learning errors in the process, but hopefully somebody can learn from it and even with errors costing me extra I still think I save a lot what dealer would charge me.

Coming to the point. The exhaust leak thru the injector seal melted the sound dampening (?) foam on the top of the head. The melted plastic filled up whole injector cavity as well the bolts holes. We are talking about 70 mm long and only 6 mm dia bolts, while injector bodies are even longer. So my first error was underestimating the strength of plastic. I started taking the injector out and pry the plastic out of the bolts and rocker holding the injector.

Error number one -the hardened plastic was stronger than paper-thin valve cover. The used screwdriver instead of lifting the plastic off -pushed hole in the cover.

While waiting for new cover and injector removal tool, I learned that it is VERY advisible to do the job on hot engine what keeps the plastic and gunk softer. It was too late for me.

In the following results one of the bolt broke off. If you think drilling out 6 mm bolt in 70 mm long aluminium head is easy -think again. I spread the job over several days to avoid bloody blisters.

Even with the priceless ($70) tool the glued injector took about 2 hr of pounding and using different softeners to move out. What finally worked for me was "Goof off" what is powerful paint remover. Supposable some of carburetor cleaners can soften the melted plastic as well.

In the result I decided to replace 2 beaten up injector since they already had 145k on them. At $570 retail (a piece) they are not cheap. Thank God for Internet dealers.

Than for damaged bolt hole I had to buy helicoils set. Standard sets had the insert only 9 mm long, but at Grainger I bought a set with the tools that had helicoils 12 mm long.

So on the following picture #1 you see injector, seal (below) bolt, tap (couldn't find extended tap, so had to use vise-grip to get to the bottom of the hole) and the helicoil insert tool.

Picture #2 show my improvement for the bolts in case another leak happens in the future. Hopefully some Teflon tape on the top of the thread will stop plastic from flowing down the thread.

Picture #3 is injector with "never seize" applied on the body. The factory grease did zip to prevent the situation.

Picture #4 shows the tool

Whoever has the car with 320cdi engine (I bet it might apply to other engines) better check it out before warranty expires. The small leak can go undetectable for thousands of miles till the damage extends to big proportion.

Coming to technical part. Being curios DIY I took the top engine cover and head foam insert off -to discover look like this

At the moment with engine running I heard some hissing coming from the injector in the center, but it was actually the one on right hand side that gave me big trouble. I did some learning errors in the process, but hopefully somebody can learn from it and even with errors costing me extra I still think I save a lot what dealer would charge me.

Coming to the point. The exhaust leak thru the injector seal melted the sound dampening (?) foam on the top of the head. The melted plastic filled up whole injector cavity as well the bolts holes. We are talking about 70 mm long and only 6 mm dia bolts, while injector bodies are even longer. So my first error was underestimating the strength of plastic. I started taking the injector out and pry the plastic out of the bolts and rocker holding the injector.

Error number one -the hardened plastic was stronger than paper-thin valve cover. The used screwdriver instead of lifting the plastic off -pushed hole in the cover.

While waiting for new cover and injector removal tool, I learned that it is VERY advisible to do the job on hot engine what keeps the plastic and gunk softer. It was too late for me.

In the following results one of the bolt broke off. If you think drilling out 6 mm bolt in 70 mm long aluminium head is easy -think again. I spread the job over several days to avoid bloody blisters.

Even with the priceless ($70) tool the glued injector took about 2 hr of pounding and using different softeners to move out. What finally worked for me was "Goof off" what is powerful paint remover. Supposable some of carburetor cleaners can soften the melted plastic as well.

In the result I decided to replace 2 beaten up injector since they already had 145k on them. At $570 retail (a piece) they are not cheap. Thank God for Internet dealers.

Than for damaged bolt hole I had to buy helicoils set. Standard sets had the insert only 9 mm long, but at Grainger I bought a set with the tools that had helicoils 12 mm long.

So on the following picture #1 you see injector, seal (below) bolt, tap (couldn't find extended tap, so had to use vise-grip to get to the bottom of the hole) and the helicoil insert tool.

Picture #2 show my improvement for the bolts in case another leak happens in the future. Hopefully some Teflon tape on the top of the thread will stop plastic from flowing down the thread.

Picture #3 is injector with "never seize" applied on the body. The factory grease did zip to prevent the situation.

Picture #4 shows the tool