Hello everyone, I have been following this forum for couple of years, but now I have actually signed up and this is my first post.

The problem I am having is with battery voltage fluctuation. Using an inbuilt feature of bluetooth OBD scanner (measuring the system voltage), I have discovered that system voltage varies from 13.4V to 14.2V seemingly random. This happens in a very slow manner, so I guess I wouldn't call it fluctuation but changing over time. During one driving cycle it may be between 13.4V and 13.8V and next cycle it might be 14.2V. The voltage changes have been definitely confirmed with multi-meter. Voltage shown by scanner is exactly what multi-meter shows at the battery terminals.

This would be all fine if there weren't any consequences to it. However, when the voltage is in the low range, it seems that the whole car starts slightly "playing up". Also, if I close a door and the window moves up (feature of W209), the voltage dips further and the idle drops slightly just for the moment (consequence of voltage dip I assume, to do with injector being influenced, or any other electrical/electronic component/sensor). Switching any other "heavy" load will cause otherwise stable idle to drop momentarily.

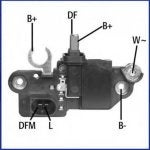

Due to worn brushes on the old regulator, I installed a new regulator some three months ago. It is a Bosch unit bought on Ebay (I know) that even says Made in Hungary. It was advertisied as genuine bosch regulator.

My question: Is the regulator supposed to charge the battery always (as is evidenced by fact that battery voltage never goes below 13.4V under normal driving operation) and keep the voltage to be close to 14.5V most of the time? Or is the regulator smart and charges according to demand and current draw of the battery and load? I can't find any info on this in the WIS.

Put in other words, Is the voltage regulator supposed to hold one FIXED voltage level under all circumstances (except during cranking and abrupt electrical load changes), and what is that voltage?

Help and suggestions appreciated by anyone.

The problem I am having is with battery voltage fluctuation. Using an inbuilt feature of bluetooth OBD scanner (measuring the system voltage), I have discovered that system voltage varies from 13.4V to 14.2V seemingly random. This happens in a very slow manner, so I guess I wouldn't call it fluctuation but changing over time. During one driving cycle it may be between 13.4V and 13.8V and next cycle it might be 14.2V. The voltage changes have been definitely confirmed with multi-meter. Voltage shown by scanner is exactly what multi-meter shows at the battery terminals.

This would be all fine if there weren't any consequences to it. However, when the voltage is in the low range, it seems that the whole car starts slightly "playing up". Also, if I close a door and the window moves up (feature of W209), the voltage dips further and the idle drops slightly just for the moment (consequence of voltage dip I assume, to do with injector being influenced, or any other electrical/electronic component/sensor). Switching any other "heavy" load will cause otherwise stable idle to drop momentarily.

Due to worn brushes on the old regulator, I installed a new regulator some three months ago. It is a Bosch unit bought on Ebay (I know) that even says Made in Hungary. It was advertisied as genuine bosch regulator.

My question: Is the regulator supposed to charge the battery always (as is evidenced by fact that battery voltage never goes below 13.4V under normal driving operation) and keep the voltage to be close to 14.5V most of the time? Or is the regulator smart and charges according to demand and current draw of the battery and load? I can't find any info on this in the WIS.

Put in other words, Is the voltage regulator supposed to hold one FIXED voltage level under all circumstances (except during cranking and abrupt electrical load changes), and what is that voltage?

Help and suggestions appreciated by anyone.