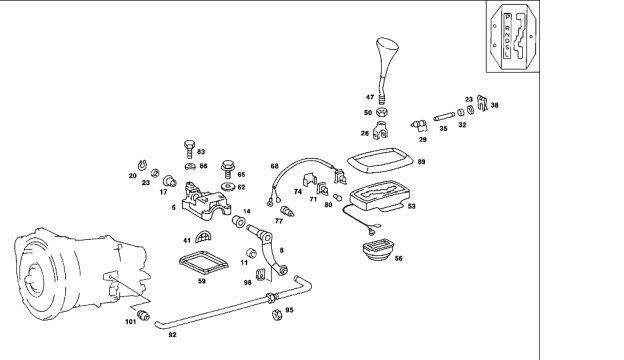

This is a guide for how to replace the 2 bushings inside the console. I didn’t replace the other 2 bushings on the rod going to the tranny because they were still good.

You’ll need:

Plilips head screw driver

Flat head screw driver

Snap ring pliers

¼ 10mm socket

¼ ratchet and extension

15mm wrench

Wheel bearing grease

2 bushings 115 267 12 50

1. Push the metal tab down a remove the ashtray:

![Image]()

2. Remove both Philips head screws:

![Image]()

3. Pull the bracket out and unplug the connector:

![Image]()

4. Pull the front part of the wood up and slide back then unplug all switches:

![Image]()

5. Pry out the shifter light:

![Image]()

6. Remove all 3 10mm bolts that hold the shifter gate in place:

![Image]()

7. Twist the shifter gate to the side and use a 15mm wrench and loosen the lock nut and then finish turning the shifter knob counter clock-wise until it is off:

![Image]()

You’ll need:

Plilips head screw driver

Flat head screw driver

Snap ring pliers

¼ 10mm socket

¼ ratchet and extension

15mm wrench

Wheel bearing grease

2 bushings 115 267 12 50

1. Push the metal tab down a remove the ashtray:

2. Remove both Philips head screws:

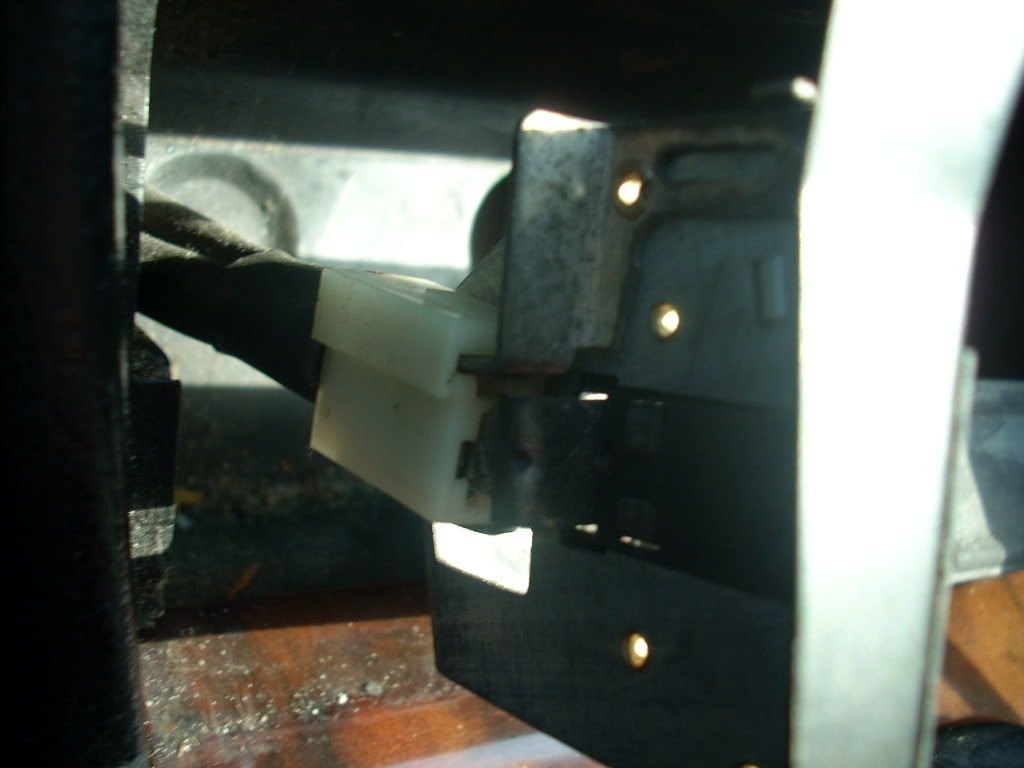

3. Pull the bracket out and unplug the connector:

4. Pull the front part of the wood up and slide back then unplug all switches:

5. Pry out the shifter light:

6. Remove all 3 10mm bolts that hold the shifter gate in place:

7. Twist the shifter gate to the side and use a 15mm wrench and loosen the lock nut and then finish turning the shifter knob counter clock-wise until it is off: