Steve, all

I jacked up the rear today and pulled pieces off to get some pics.

First off, you need a special tool to do the adjustments on the eccentric bolts. The eccentric bolts (68, 98, 149) have a very special socket head. It's a triple square, not a torx (Tork are 8 point, triple square are 12 point). The only place I could find the socket and bit were King Tony tools in the UK. That was fun ordering them in. The first pic is how I welded up the bit to fit in the confined space behind the rotor shield.

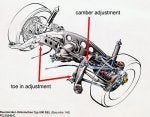

There are two adjustments that should be made to alter the camber: the forward and the rearward upper arms (92 and 62 respectively). Both of these attach to top of the the spindle with eccentric bolts. I took a shot of these from above the rotor shield. The rear arm is on the left side of the pic; the front arm is on the right side. Altering these does not seem to effect the toe very much. This pic was taken from the drivers side of my LHD.

The rear arm (62) I adjusted by using the special tool I welded up from the triple square bit. It's a bit crude, but it fits in the really tight space behind the rotor shield. In the middle picture, the forward arm adjustment is made from the right side. Sorry I couldnt get a clear picture of the head of the eccentric. You can see the nut fitted to the bolt on the left side of the arm. For this adjustment, you don't have to remove the wheel, caliper or rotor. The 3rd picture shows the adjustment for the forward arm as seen from the outside of the dust shield. For identification, the wrench is sitting on the rear arm.

The forward arm (92) is adjusted by taking off the caliper and rotor, adjusting, then replacing the rotor in order to mount the alignment mirror.

I know that both of these affected the camber, as I was watching the display of the alignment machine in real time from the pit under the car. Neither the caster or the toe were affected much for adjusting either of these arms.

The toe is adjusted by eccentric bolt 149 on arm 140.

I hope this helps someone. It's not complicated. The hardest part was getting the eccentric bolts and the correct bit for them. It's a 10mm triple square.

Cheers