My rear wiper starting running intermittently ... stopping and starting. I knew exactly what was wrong with it. I had the same problem with both wiper motors on my previous barn door version. They have a known built in fault that’s easy to rectify but you’ve got to catch them before it gets really bad. It will usually manifest after a few years or so. The washer water goes through the centre of the wiper shaft and what happens is water leaks under pressure and fills up the gearbox with water and it sits there and corrodes. There's no way for the water to drain. You've got various metals in there ... steel, zinc coating, brass, copper, solder which sets up an electroylitic reaction. It corrodes the brass plate on the back of the gearwheel that provides the switching mechanism. This happens to all of them and Mercedes do a roaring trade selling new rear wiper motors for a small fortune. Here in Australia the dealers want about $450 a motor.

So I’m sharing all I’ve learnt about Vito wiper motors:

The wiper motor after removing the internal panel and wiper arm from the outside. Pull out electrical connector and prise off the white plastic water connection fitting:

![Image]()

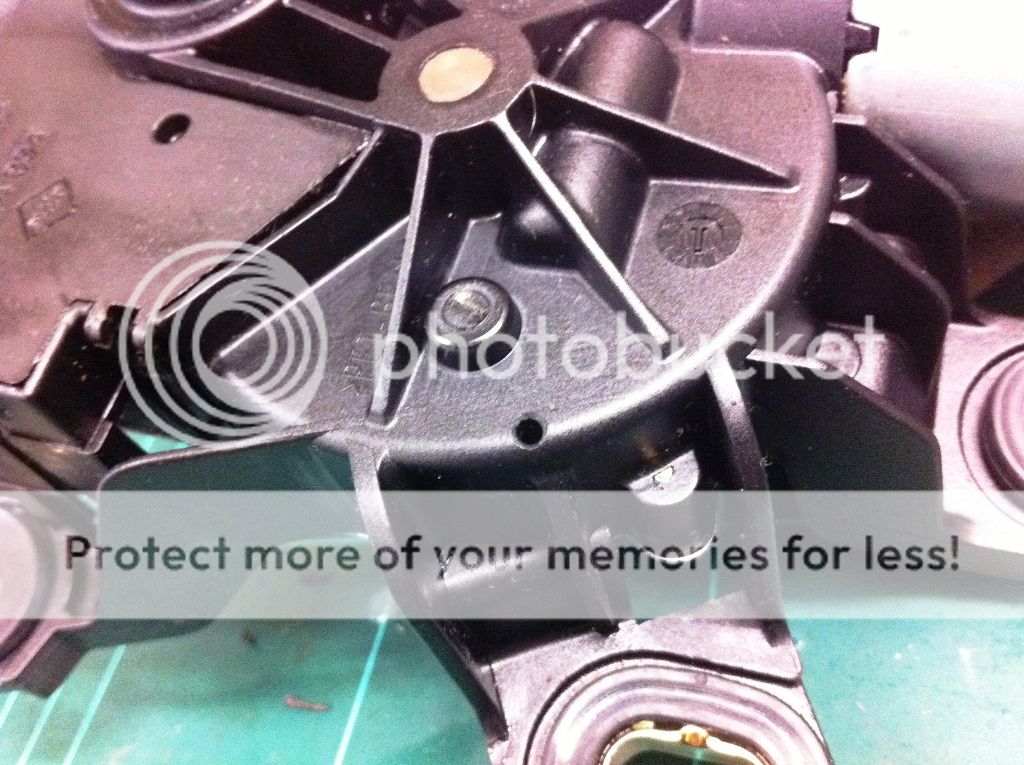

I've removed the wiper motor unit, put it on the bench and removed the metal zinc coated cover ... brown rusty water ran out ... just look at the corrosion inside. The brown is rust mixed into the white lithium grease:

![Image]()

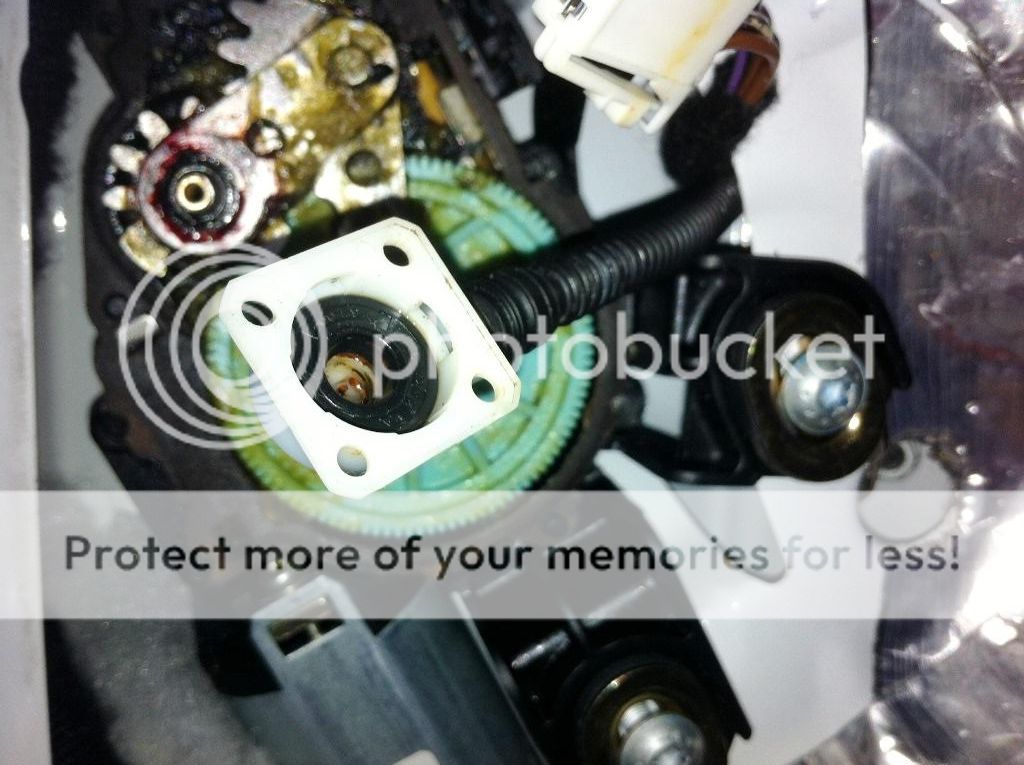

Look at the copper sulphate as a result of the corroding brass on the rear of the gear wheel. Leave this too long and it eats the brass away. On my last Vito I had to cut some thin brass sheet to shape and solder onto what was remaining as a lot had dissappeared. The levers, shaft and gearwheel all just pull out of the body. Take a photo first so you put the parts back in the right position. The corrosion causes the poor electrical contact and the stop start operation:

![Image]()

Here's the gearwheel and cover after cleaning up with degreaser and some wire brushing and wet/dry abrasive paper, you can see the zinc plating has been eaten away in some areas of the cover:

![Image]()

Here's the main body after cleaning and tidying up the contacts and the worm drive from the motor. I cleaned the electrical contacts with some wet/dry abrasive paper:

![Image]()

You can see how the levers were being eaten away. I cleaned these with degreaser then used the wire wheel on the bench grinder to remove the rust:

![Image]()

Here's the gearwheel and levers after re-installing and giving a liberal spray of lithium grease. First modifcation is to fit two o-rings onto the shaft to give it extra sealing. Smear some red rubber grease onto the o-ring:

![Image]()

Second modification is to drill a 2mm drainage hole in the lowest point of the plastic body:

![Image]()

Third and fourth modification is to drill a 2mm drainage hole in the lowest point of the metal cover and paint the cover with PlastiDip to give it an inert covering:

![Image]()

Make sure you clean the rubber seal inside the white plastic fitting that clips onto the outside of the cover plate. Smear some red rubber grease into this as well:

![Image]()

Now you should be able to reassemble and fit back into the tailgate:

![Image]()

If you get a small amount of seepage from the washers the water will drain into the door and run out of the door drain holes. While you've got the internal panel off take the opportunity to stuff some Dacron insulation bats into the door. It reduces some of the noise and makes your heating and airconditioning more efficient. I've removed all the panels in my Vito and installed Dacron insulation:

![Image]()

I hope this helps.

So I’m sharing all I’ve learnt about Vito wiper motors:

The wiper motor after removing the internal panel and wiper arm from the outside. Pull out electrical connector and prise off the white plastic water connection fitting:

I've removed the wiper motor unit, put it on the bench and removed the metal zinc coated cover ... brown rusty water ran out ... just look at the corrosion inside. The brown is rust mixed into the white lithium grease:

Look at the copper sulphate as a result of the corroding brass on the rear of the gear wheel. Leave this too long and it eats the brass away. On my last Vito I had to cut some thin brass sheet to shape and solder onto what was remaining as a lot had dissappeared. The levers, shaft and gearwheel all just pull out of the body. Take a photo first so you put the parts back in the right position. The corrosion causes the poor electrical contact and the stop start operation:

Here's the gearwheel and cover after cleaning up with degreaser and some wire brushing and wet/dry abrasive paper, you can see the zinc plating has been eaten away in some areas of the cover:

Here's the main body after cleaning and tidying up the contacts and the worm drive from the motor. I cleaned the electrical contacts with some wet/dry abrasive paper:

You can see how the levers were being eaten away. I cleaned these with degreaser then used the wire wheel on the bench grinder to remove the rust:

Here's the gearwheel and levers after re-installing and giving a liberal spray of lithium grease. First modifcation is to fit two o-rings onto the shaft to give it extra sealing. Smear some red rubber grease onto the o-ring:

Second modification is to drill a 2mm drainage hole in the lowest point of the plastic body:

Third and fourth modification is to drill a 2mm drainage hole in the lowest point of the metal cover and paint the cover with PlastiDip to give it an inert covering:

Make sure you clean the rubber seal inside the white plastic fitting that clips onto the outside of the cover plate. Smear some red rubber grease into this as well:

Now you should be able to reassemble and fit back into the tailgate:

If you get a small amount of seepage from the washers the water will drain into the door and run out of the door drain holes. While you've got the internal panel off take the opportunity to stuff some Dacron insulation bats into the door. It reduces some of the noise and makes your heating and airconditioning more efficient. I've removed all the panels in my Vito and installed Dacron insulation:

I hope this helps.