A few months back a member from this board came to our shop with a 2003 CL600 that had a serious problem with the front end sinking after being turned off for a few minutes.

The car also make a crazy crunching/cracking/dinging sound coming from the ABC pump and would not rodeo for more than a few minutes because the pump would not produce enough pressure.

Our first attempt to remedy the problem was to filter the ABC fluid but that had no effect and the car would sink to the ground after being off for about 3 minutes.

The front axle valve block was obviously malfunctioning and needs to be replaced along with the pump and the leaky high pressure expansion hose.

![Image]()

![Image]()

![Image]()

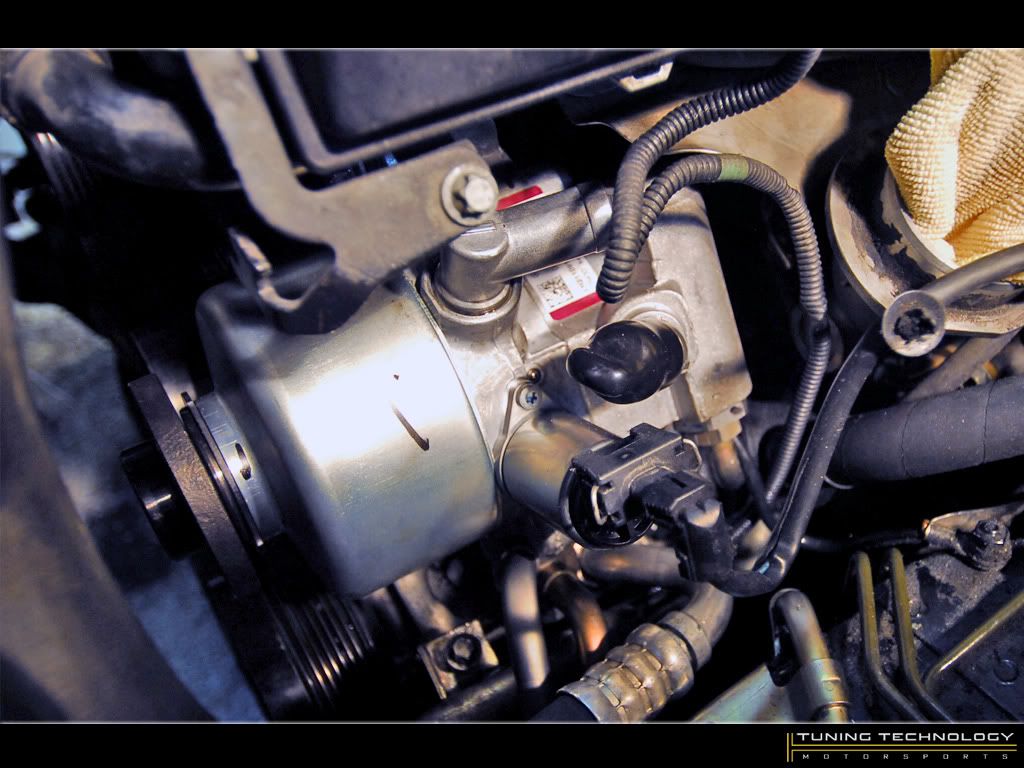

One of the first things you must do is suction off the hydraulic fluid in the ABC and PS tanks...

![Image]()

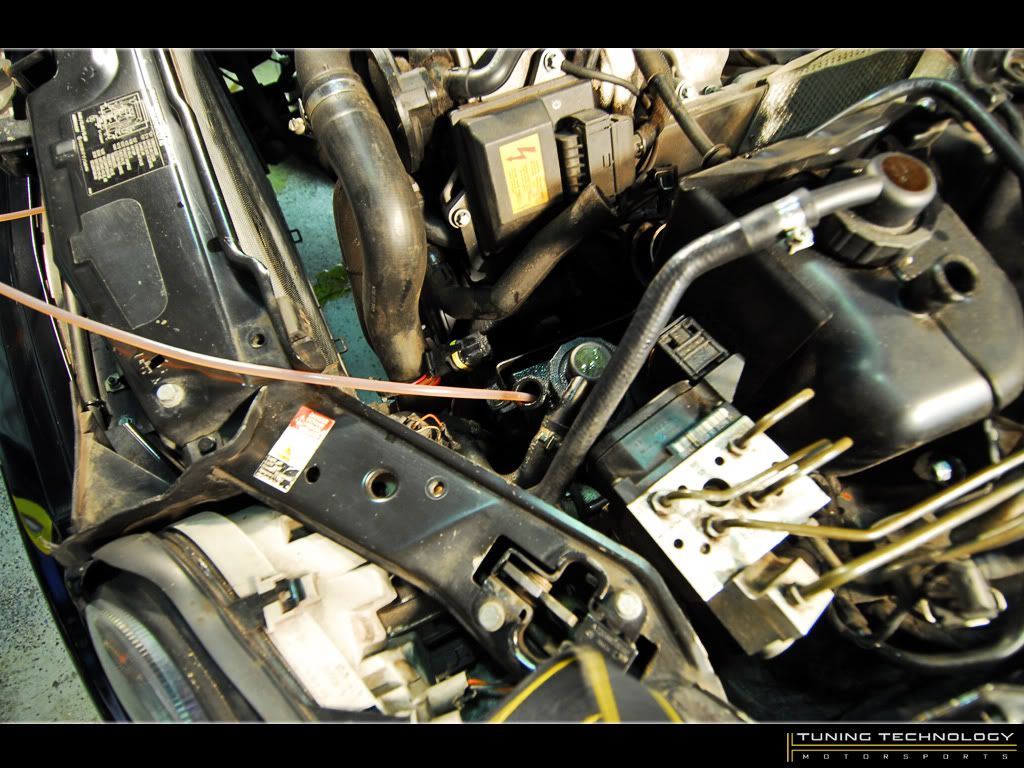

The front axle ABC valve clock hiding behind a maze of hydraulic hoses...

![Image]()

Front driver's side wheel well needs to be removed to provide access to the front axle valve block and the pressure accumulator...

![Image]()

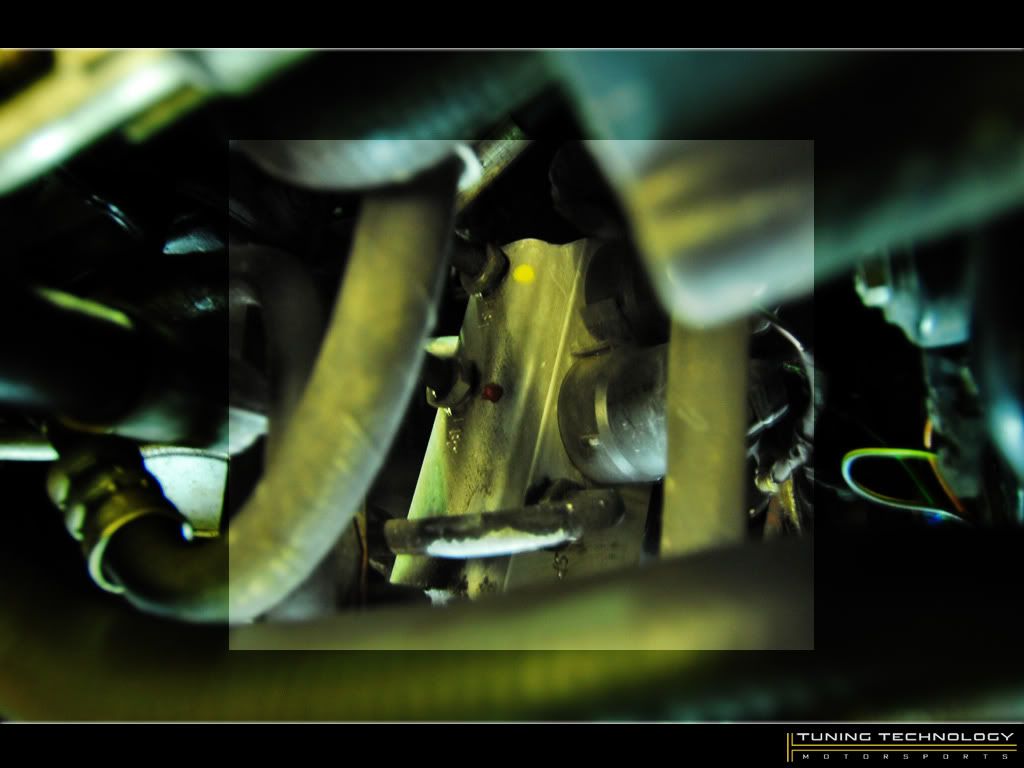

The black bulb is the front axle pressure accumulator and it is on the same plate as the front axel valve block. The whole assembly is removed once the hydraulic hoses are disconnected from the valve block...

![Image]()

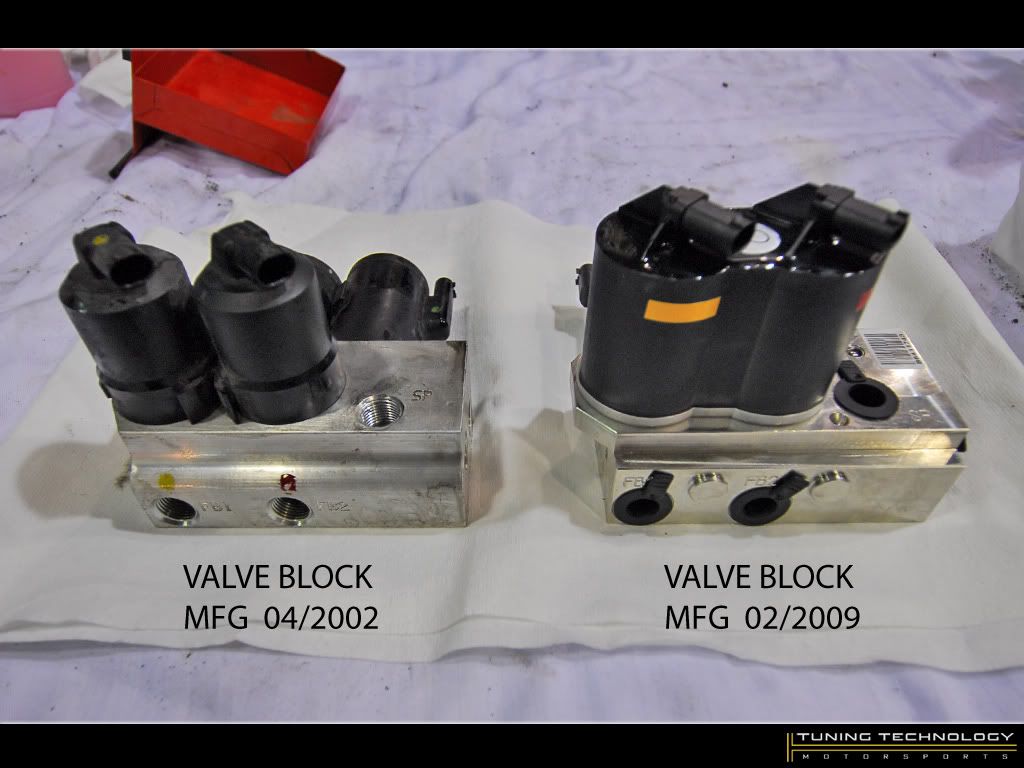

Here is what 7 years of improvement look like... the valve blocks are not manufactured by the same company...

![Image]()

![Image]()

The car also make a crazy crunching/cracking/dinging sound coming from the ABC pump and would not rodeo for more than a few minutes because the pump would not produce enough pressure.

Our first attempt to remedy the problem was to filter the ABC fluid but that had no effect and the car would sink to the ground after being off for about 3 minutes.

The front axle valve block was obviously malfunctioning and needs to be replaced along with the pump and the leaky high pressure expansion hose.

One of the first things you must do is suction off the hydraulic fluid in the ABC and PS tanks...

The front axle ABC valve clock hiding behind a maze of hydraulic hoses...

Front driver's side wheel well needs to be removed to provide access to the front axle valve block and the pressure accumulator...

The black bulb is the front axle pressure accumulator and it is on the same plate as the front axel valve block. The whole assembly is removed once the hydraulic hoses are disconnected from the valve block...

Here is what 7 years of improvement look like... the valve blocks are not manufactured by the same company...